Turbochargers have transformed engine performance, but Variable Geometry Turbochargers (VGTs) take it further by adapting to engine speed and load. Common in diesel SUVs and high-performance cars, VGTs reduce turbo lag and improve low-end torque—making them ideal for Indian driving conditions.

🔍 What Is a VGT?

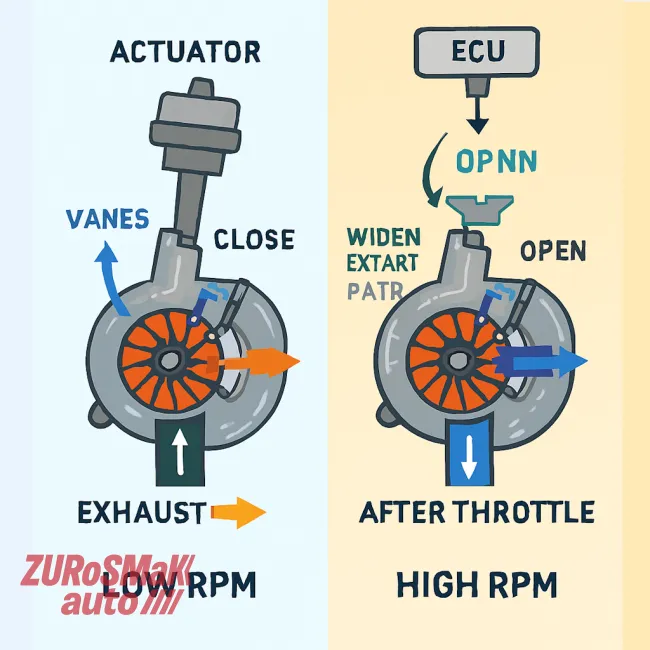

A VGT uses adjustable vanes inside the turbine housing to control exhaust flow. These vanes change their angle based on engine RPM, optimizing boost pressure across the rev range.

Image: Cutaway diagram of a VGT showing adjustable vanes around the turbine wheel

📊 VGT vs Fixed Geometry Turbo

| Feature | Fixed Turbo | VGT |

|---|---|---|

| Boost Range | Narrow | |

| Turbo Lag | High | Minimal |

| Efficiency | RPM-dependent | Adaptive |

| Cost | Lower | Higher |

Image: Side-by-side comparison of fixed and variable geometry turbochargers

🧪 How VGT Works

At low RPMs, the vanes narrow the exhaust path to increase gas velocity, spooling the turbo faster. At high RPMs, the vanes open wider to prevent backpressure. This dynamic adjustment is controlled by an actuator—either pneumatic or electronic—linked to the ECU.

🚗 Where You’ll Find VGTs

- Tata Safari / Harrier – Kryotec diesel engine with VGT

- Mahindra Scorpio-N – mHawk diesel with VGT

- Porsche 911 Turbo – Twin VGTs for high-end performance

- Commercial trucks – For torque-heavy applications

📈 Benefits of VGT

- Improved low-end torque for city driving

- Reduced turbo lag during acceleration

- Better fuel efficiency under load

- Cleaner emissions due to optimized combustion

⚠️ Challenges & Maintenance

VGTs are more complex than fixed turbos. Common issues include:

- Carbon buildup on vanes

- Actuator failure

- ECU miscalibration

Regular servicing, clean fuel, and proper diagnostics are key to VGT longevity.